You want the best fiber laser cutter for 2025, right? Top models include KRRASS, xTool P2, Cloudray, Wisely, BWM Tech, and TRUMPF. Choosing the right laser cutter can change how you work. It helps if you run a factory, a small shop, or work at home. Each fiber laser cutting machine has special benefits. They work well for factories, small businesses, and creative hobbies. Think about your materials, power needs, and what you want to make before you decide.

- Fiber laser cutters are fast, accurate, and can cut many metals.

- You save money because they cost less to run and waste less material.

- These machines help factories make more things and make DIY projects easier.

Table of Contents

Key Takeaways

Fiber laser cutters work quickly and cut very accurately. They are great for many metal cutting jobs. These machines help save money because they use less energy. They also help by making less waste. Pick a cutter that fits what you need. Think about the kind of material and how thick it is. Find features like automatic focus and smart software. These can make cutting easier and better. You need to take care of your laser cutter often. This helps it work well and last longer. Think about all the costs before you buy. This means the first price, how much it costs to run, and how much you can sell it for later. Brands like KRRASS and TRUMPF are good for making lots of things. xTool P2 is better for creative work. Make sure your machine can be upgraded in the future. Good support after you buy is important too.

Fiber Laser Cutter Overview 2025

What Is a Fiber Laser Cutter

You may wonder how a fiber laser cutter is different. This machine uses a solid-state laser. It makes light with special elements like erbium. The laser goes through a fiber optic cable. It puts strong energy on metal. This energy melts or turns the metal into gas. You get a clean and exact cut. CO2 lasers use gas, but fiber laser cutters are faster. They also need less care. Look at the table below to see the main differences:

| Feature | Fiber Laser Cutters | CO2 Laser Cutters |

|---|---|---|

| Laser Generation | Solid-state elements (e.g., erbium) | Gases (e.g., CO2, nitrogen) |

| Wavelength | Short (about 1 micrometer) | Long (10.6 micrometers) |

| Cutting Speed | High | Lower, especially on shiny metals |

| Maintenance | Minimal | More frequent |

| Application | Automotive, metal art, kitchenware | Versatile, less effective on metal |

You get the same cut every time. The laser does not touch the metal. This means there is less heat damage. Fiber laser cutters are great for making metal parts, car parts, and kitchen tools.

Key Benefits for Metal Cutting

Using a fiber laser cutter gives you many big benefits:

- You can cut 1mm stainless steel much faster than with a CO2 laser. You finish jobs sooner.

- The machine is very exact. You can make small, detailed designs.

- It cuts many kinds of metal, from thin to thick.

- You do not spend much time fixing the machine. There are fewer moving parts.

- Fiber laser cutters use up to half the energy of old machines. This saves you money.

- The cuts are smooth. You do not need to do much extra work.

- These machines last a long time because of their solid-state design.

If you need a metal laser cutter for a busy shop, this is a good choice.

2025 Laser Cutting Trends

Laser cutting is always changing. In 2025, some new things are happening:

- Fiber laser cutters are now the top choice. More people pick them over CO2 models. They cut faster and cost less to use.

- High-power models, like 10kW and higher, are common. You can cut thick plates easily.

- Many machines now work by themselves. They load and unload metal without help. This keeps the quality steady.

- Smart features help you work better. Machines can watch themselves and tell you when they need care.

- You can change machines to fit your needs. Modular designs let you switch parts fast.

- Saving energy is important. New machines use less power and help the planet.

See some new features in the table below:

| Advancement | Description |

|---|---|

| Improved clamping systems | Four-chuck clamping holds tubes tight and stops shaking. |

| Intelligent control software | The system picks the best settings for each job by itself. |

| Enhanced laser power | You can cut thick tubes faster and still get good results. |

These changes make fiber laser cutters smarter and faster. They are also more dependable. If you want to do well in metal work, these trends are important.

Best Laser Cutter Models Compared

KRRASS Fiber Laser Cutting Machine

Series and Power Options

KRRASS gives you many choices for laser cutting. There are different series for different jobs. The Smart High Configuration Series is good for most metal work. The Smart-Plus series can cut tubes and sheets. The Smart-Pro series has an exchange platform to help you work faster. The Large-format Fiber Laser Cutting Machine is for big projects and large sheets.

You can pick from many power levels. The power goes from 1,000W up to 20,000W. This lets you cut thin or thick metal. You can see the main specs in the table below:

| Feature | Specification |

|---|---|

| Laser Power Range | 1,000W – 20,000W |

| Supported Materials | Carbon steel, stainless steel, aluminum, brass, copper |

| Cutting Thickness | Varies by material and power |

| Cutting Speed | Fast |

| Incision Width | 0.1mm – 0.3mm |

| CNC Programming | Yes |

| Automation | Automatic typesetting |

| Application | Industrial, fabrication, manufacturing |

Key Features and Advantages

KRRASS uses new technology to help you work better. You get smooth and flat cuts every time. The machine works with many metals, so you can do lots of projects. It saves energy and keeps costs low. The cuts are so clean that you do not need much extra work.

- You can cut hard shapes without trouble.

- The machine keeps your metal safe from heat.

- Every part looks the same each time.

- CNC programming helps you set up jobs fast.

- Automatic typesetting helps you use all your material.

Tip: KRRASS is a good choice if you want a strong machine that lasts.

Ideal Applications

You can use KRRASS in many places. It fits in factories, metal shops, and plants. It can cut carbon steel, stainless steel, and aluminum. You can make car parts, kitchen tools, metal art, and signs. KRRASS is best for people who want fast, accurate, and cheap cutting.

xTool P2 Laser Cutter

Notable Features

The xTool P2 Laser Cutter has many smart features. It uses a 55W CO2 laser for strong cutting. The working area is big at 1,000 x 639 mm. It has two cameras for perfect alignment and easy checks. The air assist keeps your cuts clean by blowing away dust.

| Feature | Description |

|---|---|

| Laser Power | 55W CO2 laser |

| Working Area | 1,000 x 639 mm |

| Max Speed | 600 mm/s |

| Dual Camera System | For precise alignment |

| Pass-through Slot | For oversized materials |

| Curved Surface Engraving | Works on bottles, glasses, and more |

| Batch Processing | Engrave multiple items at once |

| Safety Features | Proximity limit switches |

You can use Lightburn software for more control. The pass-through slot lets you use long materials. Batch processing helps you engrave many things at once.

User Scenarios

The xTool P2 is great for creative people. It is good for hobbyists, small shops, and schools. You can cut and engrave wood, acrylic, leather, and more. The controls are easy to use, even for beginners. The dual cameras help you get perfect cuts every time. If you want to make gifts, signs, or art, this machine is a good fit.

Cloudray Fiber Laser Cutter

Product Range

Cloudray has many fiber laser cutters to choose from. There are models for both beginners and businesses. Machines like the UV-P-5 and MP-60 Neo show Cloudray’s new ideas. You can pick different power levels and work areas. This helps you find a machine for your project and budget.

- Cloudray machines are good for engraving and cutting.

- You can use them on metal, plastics, and more.

- There are options for new users and experts.

Reliability and Support

Cloudray machines work well for a long time. The brand makes laser cutters for your needs. Many people say the machines last and work well. Cloudray gives good customer support if you need help. The company’s focus on new tech and options means your machine can grow with your business.

Note: Cloudray is a smart pick for both new and experienced users because of its strong support and reliable machines.

Wisely Fiber Laser Cutter

High-End Features

You want a machine that brings advanced technology to your workshop. Wisely Fiber Laser Cutter stands out with its high-end features. You get a powerful system that handles both thin and thick metals. The machine uses a stable laser source, so you see consistent results every time. You can rely on its automatic focus system. This feature helps you switch between different materials without stopping to adjust settings. The machine also comes with a smart cooling system. It keeps the laser at the right temperature, even during long cutting sessions.

You control the Wisely machine with easy-to-use software. The interface feels simple, so you set up jobs quickly. You can upload your designs and start cutting in just a few steps. The machine supports a wide range of file formats. This flexibility lets you work with many design programs. Safety features protect you and your team. The enclosure blocks stray light, and sensors stop the machine if you open the door.

Value Proposition

Wisely gives you a strong value for your money. You get a fiber laser cutter that works for both small shops and growing businesses. The machine cuts fast and keeps your costs low. You save time because you do not need to finish the edges after cutting. The smooth cuts look professional right away. Wisely machines last a long time, so you do not worry about frequent repairs.

If you want to expand your business, Wisely helps you scale up. The machine handles large orders and custom projects. You can take on new clients and offer more services. Many users say Wisely offers great support. You get help when you need it, which keeps your work on track.

BWM Tech Laser Cutter

Performance Highlights

BWM Tech brings you a laser cutter built for speed and precision. The machine uses advanced motion control, so you see sharp lines and clean edges. You can cut stainless steel, aluminum, and brass with ease. The high-speed motors move the cutting head quickly across the work area. This speed means you finish jobs faster and take on more work.

You also get a large working table. You can place big sheets of metal on the table without trouble. The machine supports both single and batch cutting. This flexibility helps you handle different types of orders. The dust extraction system keeps your workspace clean. You spend less time cleaning up and more time working.

Target Users

BWM Tech designs its machines for busy shops and factories. If you run a business that needs fast turnaround, this machine fits your needs. You can use it for metal signs, machine parts, or custom projects. The easy controls help new users get started quickly. Experienced operators can fine-tune settings for special jobs. BWM Tech offers training and support, so you always have help nearby.

TRUMPF TruLaser Series

Technology Overview

TRUMPF TruLaser Series leads the way in laser cutting technology. In 2025, you see new features that make your work easier and more reliable. The BrightLine Scan technology stands out. This system improves the quality and stability of your cuts. You guide the laser beam with both the robot and the optics at the same time. This dual guidance gives you more control and better results, especially during complex cutting or welding tasks.

You also notice the machine’s robust construction. TRUMPF builds its machines to last in tough environments. The software offers smart automation. You can set up jobs, monitor progress, and adjust settings from a single screen. The machine keeps track of maintenance needs and alerts you before problems start.

Market Position

TRUMPF holds a strong place in the market. Many large factories and advanced workshops choose this brand. You get a machine that handles high-volume production without slowing down. The company’s focus on innovation means you always have access to the latest features. TRUMPF’s support team helps you solve problems quickly. If you want a top-tier laser cutter for demanding jobs, the TruLaser Series gives you the tools you need.

Laser Cutter Feature Comparison

Power and Material Capability

Wattage Range

When you look at a fiber laser cutter, you notice the wattage first. The wattage tells you how powerful the machine is. Most laser cutters in 2025 come with a wide range of power options. You can find machines as low as 10W and as high as 60,000W. This big range means you can pick a machine that fits your needs.

- Lower wattage works best for small projects or thin materials.

- Higher wattage lets you cut thick metal fast.

- Industrial shops often choose high-power models for high-speed cutting and heavy-duty jobs.

If you want to cut thick steel or work faster, you should pick a higher wattage. For crafts or light work, a lower wattage saves money and energy.

Supported Materials

You want a laser cutter that handles many materials. Fiber laser cutters shine when you work with metals. They cut stainless steel, carbon steel, and even tough alloys. Some models also handle aluminum and copper with ease. If you need to cut non-metal materials, you might look at CO₂ or hybrid systems.

Here’s a quick look at what each type can do:

| Material Type | Fiber Lasers | CO₂ Lasers | Hybrid Systems |

|---|---|---|---|

| Stainless Steel | Yes | Yes | Yes |

| Carbon Steel | Yes | Yes | Yes |

| Alloy Steel | Yes | Yes | Yes |

| Silicon Steel | Yes | Yes | Yes |

| Spring Steel | Yes | Yes | Yes |

| Aluminum | Yes | Limited | Yes |

| Aluminum Alloys | Yes | Limited | Yes |

| Non-Metal Materials | No | Yes | Yes |

You see fiber laser cutters in many industries. People use them in automotive, machinery, and tool manufacturing. You can cut body parts, engine pieces, and even tool blades. Fiber lasers give you speed, precision, and flexibility for metal jobs.

Speed and Precision

Cutting Speed

Cutting speed matters when you want to finish jobs quickly. High-speed cutting helps you take on more work and meet tight deadlines. Fiber laser cutters lead the way in this area. You get fast results, especially with higher wattage models. If you run a busy shop, you will notice the difference right away.

Accuracy

You want every cut to look sharp and clean. Cutting accuracy sets the best machines apart. Mid-range and high-end models give you better precision, especially for detailed designs or engraving. Budget models may not match this level, but they still work well for simple shapes.

| Feature | Mid-Range Models | Budget Models |

|---|---|---|

| Precision | Higher precision in engraving | Lower precision |

If you need perfect edges or small details, choose a machine with high accuracy. This helps you avoid extra finishing work and keeps your products looking professional.

Work Area and Size

Table Dimensions

The size of the work area decides how big your projects can be. Many leading models offer large tables. For example, some machines give you a 5ft x 10ft work area. This space lets you cut big sheets or handle multiple parts at once.

Space Requirements

Think about your workshop before you buy a metal laser cutter. Bigger machines need more room. You should measure your space and make sure you have enough clearance for loading and unloading materials. Smaller models fit well in tight spaces or small shops. Always check the machine’s footprint before you decide.

Tip: Pick a laser cutter that matches your project size and shop space. This helps you work safely and efficiently.

Software and Automation

CNC and Programming

You want a fiber laser cutter that is easy to use. New machines have smart CNC systems. These systems help you control the laser’s movement. You can set up jobs and change designs quickly. Most brands offer simple software. You do not need special skills to start.

Look at how some brands compare:

| Manufacturer | CNC Capabilities | Programming Features |

|---|---|---|

| OPMT Laser | High-precision multi-axis CNC | Dual laser heads for efficiency |

| Whitney | Fiber optic technology | Advanced cutting head integration |

| Mitsubishi | Solid construction | High-quality outputs |

Each brand has something unique. Some focus on very exact moves. Others help you set up faster or get better results. These features give you more control and better cuts.

Integration Options

Automation is very important in 2025. You want your laser cutter to work with other machines. Many models connect to the cloud. This lets you check your machine from anywhere. Some machines use AI to pick the best settings. You can get alerts when your machine needs care.

Here is what you might see:

| Model Description | Key Technologies |

|---|---|

| High-mix, high-volume shops | AI-driven parameter adjustment, Cloud connectivity |

| Extreme versatility, top quality | BrightLine fiber technology, Integrated material storage |

| Job shops and fabricators | Auto Nozzle Change, Auto Focus |

| Large-scale operations | Material handling robotics, Cell management software |

You can link your laser cutter to robots or storage. This saves time and helps you cut faster. Smart software keeps your shop working well.

Safety and Maintenance

Safety Features

Safety is very important when using a fiber laser cutter. Most machines have strong covers. These keep the laser light inside and protect your eyes. Sensors stop the machine if you open a door or if something is wrong. Some machines use cameras to watch the cutting area. You feel safe while working.

Many brands add things like emergency stop buttons and alarms. You can work without worry. The machine will warn you if there is a problem.

Tip: Always look at safety features before buying a laser cutter. Good safety means fewer accidents and easier work.

Maintenance Needs

Taking care of your machine is easy if you follow a plan. Regular checks help you find problems early. You avoid stopping work and keep cutting fast. Here is a simple guide for care:

| Maintenance Frequency | Tasks |

|---|---|

| Daily | Check laser and gas pressure, clean nozzle, check water level |

| Weekly | Check air filters, lubricate parts, clean dust from control cabinet |

| Monthly | Inspect nozzles, update software, check coolant levels |

| Quarterly | Perform full calibration, inspect the whole system |

| Annually | Replace worn parts, overhaul system, provide operator training |

You want your machine to last many years. Regular care keeps cuts sharp and costs low. Here are reasons to follow a care plan:

- You avoid big problems and save money.

- Your machine keeps making good cuts.

- You get more years from your machine.

If you take care of your fiber laser cutter, it will help your business.

Brand Reputation and User Feedback

KRRASS Reviews

People from many countries talk about KRRASS Fiber Laser Cutting Machines. They say the machine is built strong and uses good materials. Reviews come in many languages, so KRRASS is popular worldwide. Customers are happy with how well the machine cuts and how reliable it is.

Here’s what users say:

| Review Type | Review Content |

|---|---|

| Positive | “Buena máquina de corte por láser de fibra. ¡Estamos muy satisfechos con su calidad, el cuerpo es fuerte, el uso de material de alta calidad!” |

| Positive | “Рекомендовать стиль Волоконно-лазерная машина для резки очень приятно” |

| Positive | “ماكينة القص QC12K 6×3200 رائعة للغاية.” |

| Negative | “I want to buy the good laser cutting machine. Please contact me.” |

Most people talk about how tough and dependable the machine is. Customers trust KRRASS for hard jobs. The few negative reviews are mostly from people who want more details or want to buy, not from unhappy users.

Tip: If you want a machine that many people trust, KRRASS is a great pick. Users around the world are happy with it.

xTool P2 User Insights

xTool P2 is used in lots of shops and studios. People like that it is easy to use and makes clean cuts. The dual camera helps you line up your designs just right. Many users say the air assist keeps dust away and makes cuts look good. You can engrave on curved things, so you can be more creative.

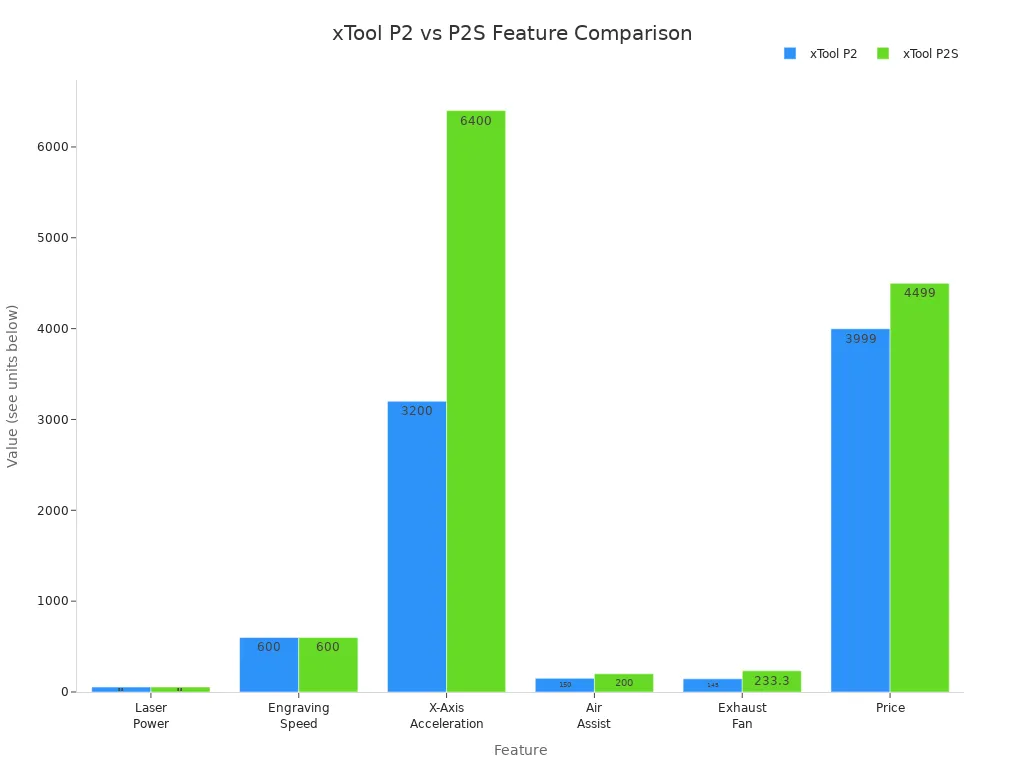

When you look at xTool P2 and the new P2S, you see some big changes. The P2S is faster, has better air assist, and a stronger fan. The camera in the P2S uses AI, so you get even better results, even on hard surfaces. The P2S costs more, but users say the new features save time and make work better.

xTool P2 is good for hobbyists and small businesses. If you want faster work and cleaner cuts, the P2S might be worth the extra money.

Note: xTool P2 is easy to use and works well. You can get the P2S if you want more speed and better cuts.

Cloudray Customer Feedback

Cloudray gets good reviews from people who need to engrave and cut. Customers like that there are many models and choices. Many users say Cloudray machines last a long time. People also like the support team and feel safe knowing help is there.

Cloudray is good for beginners and experts. The machines work with different materials, and the software is simple to learn. Customers talk about how reliable the machines are and how they help their business grow.

If you want a fiber laser cutter that fits your needs and has good support, Cloudray is a smart pick.

Wisely and BWM Tech Reputation

When you look at Wisely and BWM Tech, you see two brands that get a lot of attention in the laser cutting world. People talk about them for different reasons, but both have built strong reputations.

Wisely Fiber Laser Cutter

You hear a lot of good things about Wisely. Users say the machines work well for both small shops and growing businesses. If you want a machine that feels high-end but does not break the bank, Wisely often comes up in conversations. Many people like the automatic focus system. You do not have to stop and adjust settings when you switch materials. This saves you time and keeps your work moving.

Here are some things users mention about Wisely:

- The machine gives you smooth, clean cuts.

- You can switch between different metals without much hassle.

- The software feels easy to use, even if you are new to laser cutting.

- The safety features help you feel confident while you work.

“I started with a Wisely machine in my garage. Now I run a small shop. The machine keeps up with every order.” — Small business owner

People also talk about Wisely’s support team. If you run into trouble, you can reach out and get help fast. That makes a big difference when you have deadlines.

BWM Tech Laser Cutter

BWM Tech stands out for speed and reliability. You see these machines in busy shops and factories. If you need to finish jobs quickly, BWM Tech helps you do that. The large work area lets you handle big sheets of metal. You can also cut many parts at once, which helps you take on more orders.

Users highlight these points about BWM Tech:

- The machine moves fast and cuts with sharp precision.

- You get a dust extraction system that keeps your workspace clean.

- The controls feel simple, so you can start working right away.

- Training and support come with the machine, so you never feel lost.

| Brand | What Users Like Most | Best For |

|---|---|---|

| Wisely | Smooth cuts, easy software, support | Small shops, scaling up |

| BWM Tech | Speed, large table, clean workspace | Busy shops, factories |

If you want a machine that grows with your business, Wisely gives you that path. If you need to move fast and handle big jobs, BWM Tech fits the bill. Both brands make it easy for you to get started and keep working.

Pros and Cons of Top Fiber Laser Cutters

KRRASS Fiber Laser Cutter

When you look at the KRRASS Fiber Laser Cutter, you see a machine built for speed and accuracy. Many users say it works well for both small and large jobs. You can cut many types of metal with clean edges. The machine helps you save money over time because it uses less energy and needs little maintenance. If you want a reliable tool for your shop, KRRASS stands out.

Here’s a quick look at what people like and what you might want to consider:

| Advantages | Disadvantages |

|---|---|

| High speed | High initial costs |

| High accuracy | Increased complexity |

| Low operating costs | Limited access to certain materials |

| Superior edge quality | Potential issues with ventilation |

| Small kerf | N/A |

| Versatility in cutting materials | N/A |

Tip: If you want a laser cutter that gives you fast, clean, and precise results, KRRASS is a strong choice for your metalworking needs.

xTool P2 Laser Cutter

The xTool P2 Laser Cutter brings a lot of smart features to your workspace. You get a large working area, which means you can handle big projects or batch jobs. The dual camera system helps you line up your designs perfectly. You can also engrave on curved surfaces, which opens up more creative options.

Pros:

- Easy to use, even if you are new to laser cutting.

- Dual cameras make alignment simple.

- Handles a wide range of materials, like wood, acrylic, and leather.

- Batch processing saves you time on big orders.

- Safety features keep you protected.

Cons:

- The CO2 laser may not cut metal as well as a fiber laser cutter.

- The machine takes up a lot of space.

- You may need extra ventilation for safe use.

Note: If you want a flexible laser cutter for crafts, gifts, or small business projects, xTool P2 is a great pick.

Cloudray Fiber Laser Cutter

Cloudray gives you a lot of choices when it comes to laser cutting. You can pick from different models and power levels. Many users say the machines last a long time and work well for both cutting and engraving. The software is easy to learn, so you can start working quickly.

Pros:

- Wide range of models for different needs.

- Good for both beginners and experts.

- Reliable performance over time.

- Strong customer support.

- Handles metals and some non-metals.

Cons:

- Some models may have a learning curve for advanced features.

- Not all machines are suited for very thick materials.

- You may need to buy extra accessories for special projects.

If you want a dependable laser cutter with lots of options, Cloudray is worth a look.

Wisely Fiber Laser Cutter

When you look at the Wisely Fiber Laser Cutter, you see a machine that brings advanced features to your shop. You get automatic focus, which means you can switch between different metals without stopping to adjust settings. The smart cooling system keeps the laser at the right temperature, even during long jobs. You can trust the software to feel simple, so you set up your designs and start cutting fast.

Pros:

- You get smooth, clean cuts every time.

- The machine handles both thin and thick metals.

- Safety features protect you and your team.

- The software supports many file types, so you can use your favorite design programs.

- The automatic focus saves you time.

Cons:

- The machine may cost more than basic models.

- You might need some time to learn all the features.

- The size could be too big for small workspaces.

If you want a laser cutter that helps your business grow, Wisely gives you the tools to take on more orders and new projects.

BWM Tech Laser Cutter

BWM Tech builds its laser cutter for speed and reliability. You can cut stainless steel, aluminum, and brass with sharp precision. The large work area lets you handle big sheets or many parts at once. The dust extraction system keeps your workspace clean, so you spend less time cleaning up.

Pros:

- Fast cutting speeds help you finish jobs quickly.

- The machine supports both single and batch cutting.

- Easy controls make it simple for new users.

- Training and support come with the machine.

Cons:

- The machine may take up a lot of space.

- You might need to invest in extra ventilation.

- The price can be high for small shops.

BWM Tech is a good choice if you run a busy shop and need a laser cutter that keeps up with your workload.

TRUMPF TruLaser Series

You see the TRUMPF TruLaser Series in many large factories. This laser cutter stands out because TRUMPF designs almost every part in-house. The laser source, the automation software, and even the controls work together for top performance. You get a machine that feels stable and reliable, even during long cutting sessions.

Here’s a quick look at what you get:

| Advantages | Disadvantages |

|---|---|

| Exceptional cutting precision | High costs |

| High automation | Complex operation requirements |

| Advanced technology integration |

You also notice some special features:

- High-quality single-mode and multi-mode laser beams

- High cutting efficiency

- Minimal spatter during cutting

- Compact design for big jobs

- Long service life

But you should know about the challenges:

- Expensive machines

- High maintenance costs

- You need professional training to use all the features

If you want the best in cutting technology and you work in a high-volume shop, the TRUMPF TruLaser Series gives you the power and precision you need.

Laser Cutting Decision Guide

Assessing Your Needs

Choosing the right fiber laser cutter starts with knowing what you want to achieve. You need to look at your production goals and the types of materials you plan to cut. If you work with metal fabrication or high-volume production, you should pick a machine with enough power and speed. Some machines handle thin sheets, while others cut thick plates for industrial applications.

Here’s a simple way to figure out what you need:

- Check the laser power and source. Match the machine’s strength to your production demands.

- Think about versatility. Make sure the cutter works with all the materials and thicknesses you use.

- Look at supplier reliability. Pick a brand that offers strong after-sales support.

- Consider the total cost of ownership. This includes the price, maintenance, and energy use.

Tip: Write down your main applications before you shop. This helps you compare models and find the best fit.

Budget and Value

You want a laser cutting machine that fits your budget but also gives you good value. Prices can range from a few thousand dollars to much more for advanced models. Don’t just look at the sticker price. Think about how much you’ll spend over time.

Here’s what you should consider:

- Initial cost: How much does the machine cost up front?

- Operating costs: How much will you spend on energy, parts, and repairs?

- Efficiency: Will the machine help you finish jobs faster and save money?

- Resale value: Can you sell the machine later if you upgrade?

| Cost Factor | What to Check |

|---|---|

| Purchase Price | Compare models and features |

| Maintenance | Ask about service plans |

| Energy Use | Look for energy-saving technology |

| Longevity | Choose machines built to last |

A good laser engraver or cutter should help you grow your business and handle more orders. If you plan to expand, pick a model that can keep up with your needs.

After-Sales Support

After you buy your laser cutting machine, you want help when you need it. Good support makes your work easier and keeps your machine running smoothly. Some brands offer training, fast repairs, and easy access to spare parts.

Here’s what strong after-sales support looks like:

- Quick response to questions or problems

- Training for you and your team

- Easy ordering of replacement parts

- Regular updates for software and safety

Note: Ask other users about their experience with support before you choose a brand. Reliable help can save you time and money.

If you pick a machine with strong support, you can focus on your production and applications without worry.

Future-Proofing Your Investment

You want your laser cutter to last for years. Technology changes fast, so you need to think ahead. If you plan now, you can avoid problems later and keep your shop running smoothly.

Start by looking at upgrade options. Some machines let you add new features or swap out parts. This helps you keep up with new trends in laser cutting. You do not have to buy a whole new machine when you want better performance.

Think about software updates. Good brands give you regular updates. These updates fix bugs and add new tools. You stay ahead of the curve and get more from your machine. Ask the supplier how often they release updates and if you get them for free.

Check if the machine works with other equipment. You might want to add robots or smart storage in the future. If your laser cutter connects with these, you can boost your production without big changes. Look for machines that support automation and cloud features.

Here are some tips to help you future-proof your investment:

- Pick a machine with a strong frame and quality parts. It will last longer and handle more jobs.

- Choose a brand with a good track record for support and updates.

- Make sure the machine can cut new materials as they become popular.

- Ask about training for new features or upgrades.

Tip: Write down your future goals. Do you want to grow your business? Will you add new products? Use these answers to pick a machine that grows with you.

You can also use this table to check if a machine is ready for the future:

| Feature | Why It Matters |

|---|---|

| Upgradeable hardware | Lets you add power or new tools |

| Software updates | Keeps your machine current |

| Automation support | Makes your shop more efficient |

| Material flexibility | Handles new or different materials |

| Training resources | Helps you learn new features |

Laser cutting will keep changing. If you pick a machine that adapts, you will not fall behind. You save money and avoid stress. Your shop stays ready for whatever comes next.

You have a lot of great choices for laser cutting in 2025. KRRASS works best for big factories and heavy-duty jobs. xTool P2 fits creative shops and hobbyists. Cloudray and Wisely help small businesses grow. BWM Tech and TRUMPF shine in high-speed, high-volume settings. Before you buy, check the features, test the performance, and talk to suppliers. Want to see a machine in action? Request a demo and see how laser cutting can change your workflow.

FAQ

What materials can you cut with a fiber laser cutter?

You can cut metals like carbon steel, stainless steel, aluminum, brass, and copper. Some machines also handle coated metals. Fiber lasers work best on metal. For wood or plastic, you might want a CO₂ laser instead.

How do you choose the right power for your laser cutter?

Think about the thickness and type of metal you want to cut. Thicker or harder metals need more power. For most shops, 1,000W to 6,000W works well. Heavy industry often uses 10,000W or more.

Is a fiber laser cutter safe to use?

Yes, fiber laser cutters have safety covers, sensors, and emergency stops. Always wear safety glasses and follow the manual. Never open the cover while the machine runs. Safety first!

How much maintenance does a fiber laser cutter need?

You should clean the lens, check the nozzle, and inspect filters regularly. Most machines need little maintenance. Follow the care schedule in your manual. This keeps your cutter running smoothly.

Can you use a fiber laser cutter for small businesses or home workshops?

Absolutely! Many models fit small shops or home studios. Look for compact designs and lower power options. You can start with a basic model and upgrade as your business grows.

What software do you need for a fiber laser cutter?

Most machines come with their own software. You can also use popular design programs like AutoCAD or CorelDRAW. The software lets you upload designs, set cutting paths, and control the machine.

Do fiber laser cutters save money over time?

Yes! Fiber lasers use less energy and need fewer repairs than older machines. You also save on finishing work because the cuts are so clean. Over time, you spend less and get more done.