Introduction

The press brake is one of the most important machines in metal fabrication, enabling manufacturers to bend and shape sheet metal with accuracy and consistency. As technology evolves, businesses are faced with a critical decision: should they invest in a hydraulic press brake or an electric press brake?

Both models have strengths and limitations, and the choice often depends on cost, performance requirements, and specific applications. This guide will break down the differences, helping you make the right decision for your fabrication shop.

👉 Learn more about KRRASS’s company expertise in designing innovative CNC bending machines for modern industries.

1. Understanding the Basics of Press Brakes

A CNC bending machine uses advanced control systems to bend sheet metal to precise angles. The two most common types are:

- Hydraulic press brake – Uses hydraulic cylinders to apply pressure.

- Electric press brake – Uses servo-electric motors for bending action.

Both machines are widely used in metal fabrication, but their performance differs significantly.

👉 Explore KRRASS’s press brake portfolio for advanced models.

2. Hydraulic vs. Electric Press Brakes: A Side-by-Side Comparison

| Feature | Hydraulic Press Brake | Electric Press Brake |

|---|---|---|

| Power Source | Hydraulic cylinders | Servo-electric motors |

| Precision | ±0.2 mm | ±0.05 mm |

| Speed | Moderate | Very fast |

| Energy Efficiency | Higher energy use | 30–50% less energy consumption |

| Maintenance | More frequent (oil, seals) | Lower (no hydraulics) |

| Initial Cost | Lower | Higher |

| Applications | Heavy-duty thick materials | High-precision, thinner materials |

(Source: The Fabricator)

3. Advantages of Hydraulic Press Brakes

3.1 Strong Power for Heavy-Duty Work

Hydraulic systems deliver immense pressure, making them ideal for metal fabrication of thick sheets and high-strength alloys.

3.2 Lower Initial Investment

Hydraulic models typically cost less upfront, making them attractive to small and mid-sized manufacturers.

3.3 Proven Reliability

With decades of industry use, the hydraulic press brake is trusted for its durability and versatility.

4. Advantages of Electric Press Brakes

4.1 High Precision

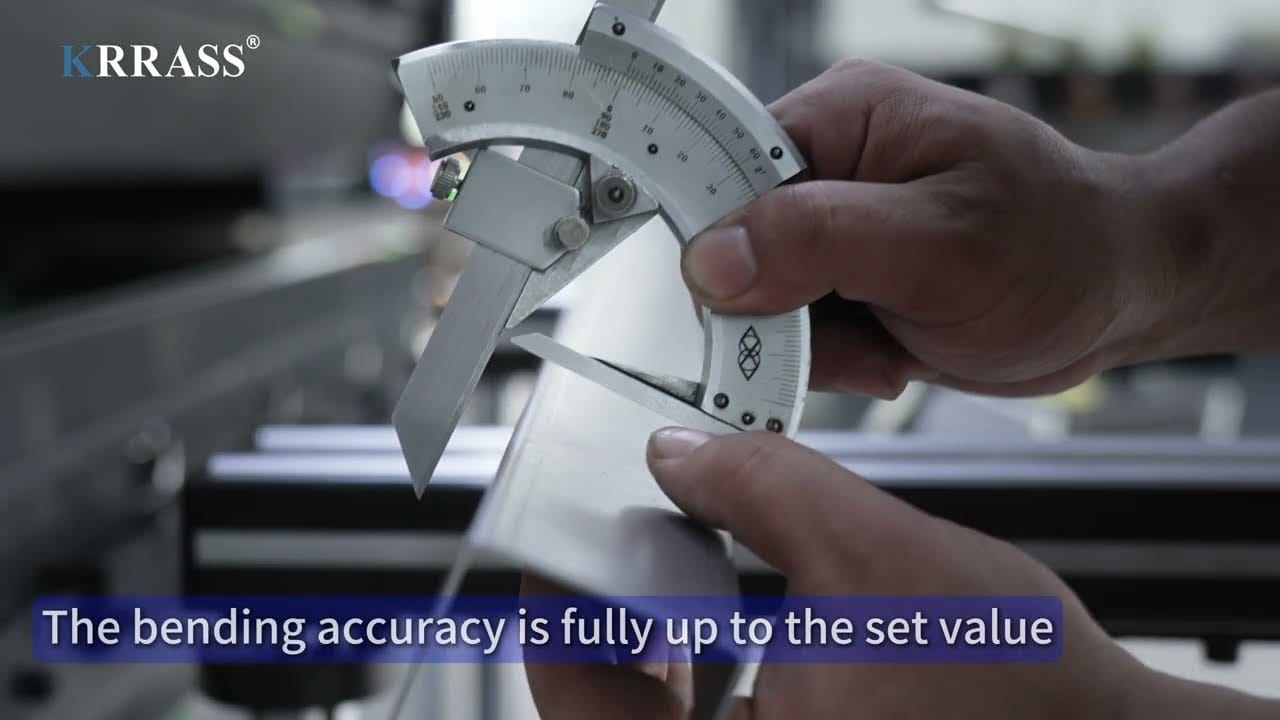

Electric models offer exceptional accuracy, making them ideal for industries like aerospace, automotive, and electronics where tolerances are tight.

4.2 Energy Efficiency

Electric press brakes consume less power, supporting sustainable manufacturing and reducing operational costs.

4.3 Lower Maintenance

No hydraulic fluids or seals mean fewer breakdowns and reduced downtime.

4.4 Faster Setup and Operation

Servo-driven systems allow rapid transitions between jobs, improving productivity in high-volume production.

5. When to Choose Hydraulic vs. Electric

- Choose a hydraulic press brake if:

- You process thicker materials (≥10 mm)

- You need a lower-cost solution

- Heavy-duty durability is more important than speed

- Choose an electric press brake if:

- You require high-precision CNC bending machines

- Sustainability and energy efficiency are priorities

- Production involves thinner materials or complex shapes

👉 Need help deciding? Contact KRRASS experts for tailored recommendations.

6. Press Brake Safety Considerations

Whether hydraulic or electric, CNC bending machines must follow strict operator protection standards:

- Use of light curtains and safety guards

- Regular maintenance and inspections

- Comprehensive operator training

(Reference: OSHA – Machine Guarding Standards)

7. The Future of Press Brake Innovation

2025 and beyond will see more hybrid press brakes, combining the strength of hydraulics with the efficiency of servo-electric systems. Smart CNC controllers and IoT integration will further improve:

- Predictive maintenance

- Real-time monitoring

- Automation with robotic arms

These innovations will define the future of metal fabrication.

8. Case Study: Transitioning from Hydraulic to Electric

A mid-sized automotive supplier replaced three hydraulic press brakes with two electric press brakes. After one year, they reported:

- 25% reduction in energy costs

- 30% faster production cycles

- Improved bending accuracy for body panels

- Lower maintenance downtime

This demonstrates how electric press brakes can improve both sustainability and productivity.

Conclusion

Choosing between a hydraulic press brake and an electric press brake depends on your business goals, material needs, and long-term strategy.

Hydraulic models offer power and affordability for heavy-duty tasks, while electric models deliver precision, speed, and sustainability. For many manufacturers, the right choice may even be a combination of both.

👉 Learn more about KRRASS’s history and expertise

👉 Browse our full range of press brakes

👉 Have questions? Contact us today

By carefully weighing the pros and cons, you can choose the CNC bending machine that ensures efficiency, safety, and profitability in the competitive world of metal fabrication.