Introduction

The sheet metal industry is experiencing a transformation. As manufacturers embrace CNC technology, new opportunities for speed, precision, and automation are emerging. In 2025, the fusion of press brake innovation, smart software, and fabrication future trends is shaping how factories design, cut, and assemble sheet metal products.

This article explores the latest CNC sheet metal trends in 2025, highlighting key innovations that will define the future of global fabrication.

👉 Learn more about KRRASS’s company expertise in advanced CNC metal processing equipment.

1. Why CNC Technology Matters in 2025

CNC (Computer Numerical Control) has become the backbone of sheet metal fabrication. By programming machines with digital commands, manufacturers achieve:

- Higher accuracy in cuts and bends

- Faster production cycles

- Reduced material waste

- Safer operations

In 2025, CNC machines are no longer standalone—they are part of fully integrated smart factories, connected through data, sensors, and automation.

2. Key CNC Technology Trends in Sheet Metal Fabrication

Here’s a summary of the top sheet metal trends shaping 2025:

| Trend | Impact on Fabrication Future | Example Technology |

|---|---|---|

| AI-Powered CNC Systems | Adaptive bending & cutting for real-time error correction | Smart press brakes with AI controllers |

| Green Manufacturing | Reduced energy use & scrap waste | Energy-efficient CNC laser cutters |

| Automation & Robotics | Faster handling & 24/7 production | Robotic arms for loading/unloading |

| Cloud Connectivity | Remote monitoring & predictive maintenance | IoT-integrated CNC dashboards |

| Hybrid Machines | Combining multiple processes in one | Laser-cutting + bending integrated lines |

(Source: The Fabricator)

3. Press Brake Innovation in 2025

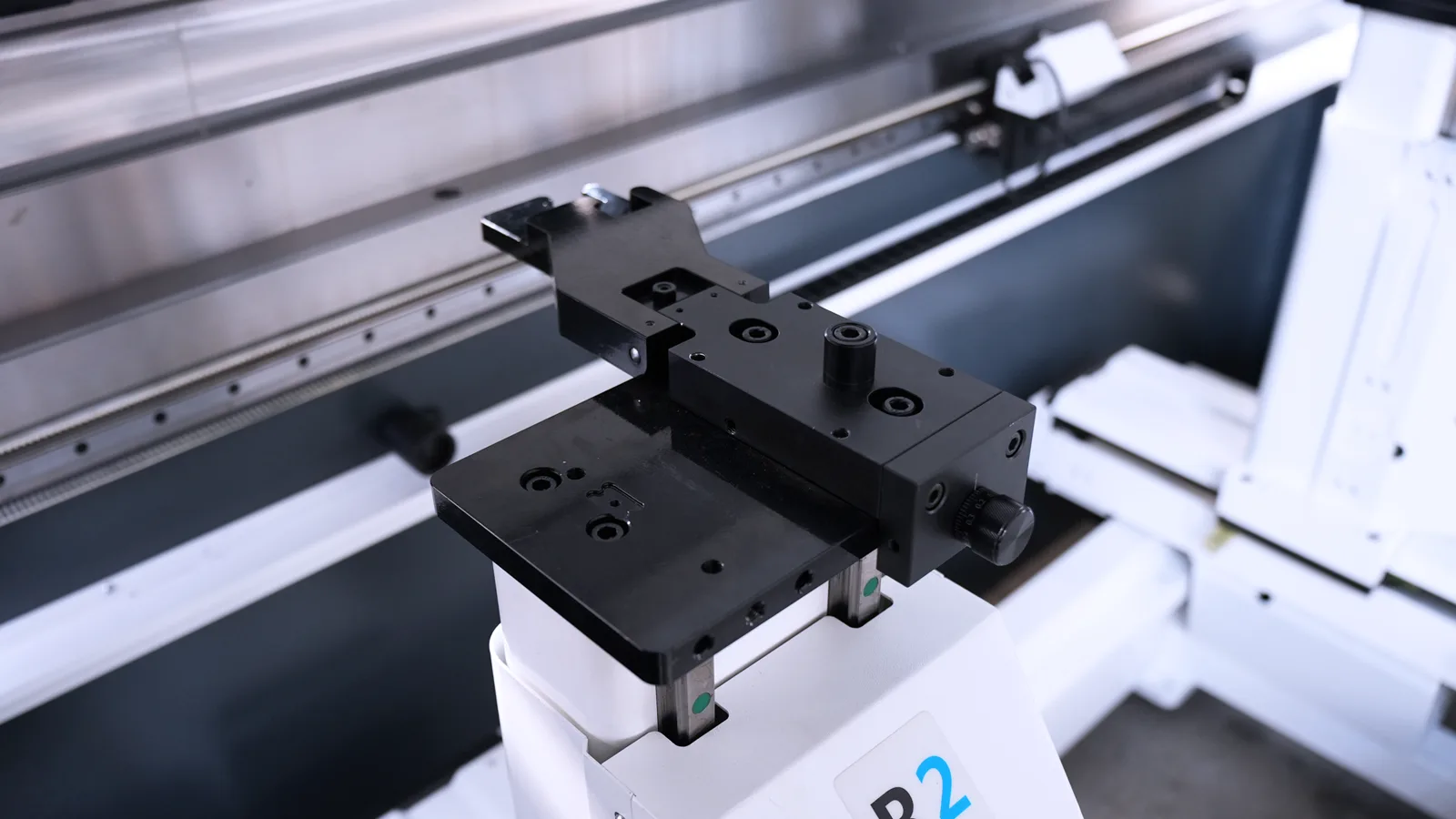

One of the most exciting aspects of CNC technology is the rise of press brake innovation.

- Smart Sensors: Measure angles in real time, ensuring accuracy without manual adjustments.

- Electric-Hydraulic Hybrids: Save up to 30% energy compared to traditional hydraulic presses.

- Robotic Integration: Automates repetitive bending tasks, freeing operators for higher-value work.

👉 Explore KRRASS’s product portfolio to see the latest CNC press brake innovations.

4. Fiber Laser Cutting and CNC Integration

CNC laser cutting is advancing rapidly:

- Speeds are increasing with fiber laser cutting technology.

- Software now automatically nests parts for maximum material efficiency.

- AI helps predict maintenance needs before downtime occurs.

Together, these trends reduce waste and deliver consistent quality across industries like automotive, aerospace, and construction.

5. Sustainability and Green Fabrication

Global industries are under pressure to reduce their environmental footprint. CNC technology supports sustainable sheet metal trends by:

- Using less energy per cut or bend

- Producing fewer emissions than plasma or CO2 cutting

- Extending tool and machine life with smart monitoring

This aligns with the sustainability goals set by organizations like the World Steel Association.

6. The Role of Automation in the Fabrication Future

Automation is no longer optional—it’s essential. CNC systems are increasingly paired with robotics and IoT solutions:

- Material handling robots feed sheets into machines automatically.

- IoT-enabled dashboards monitor performance in real time.

- Predictive analytics forecast downtime and optimize scheduling.

These changes create factories that can operate 24/7 with minimal human intervention.

7. Choosing the Right CNC Technology in 2025

When investing in CNC machines, manufacturers should consider:

- Production Volume Needs (small batches vs. mass production)

- Material Variety (mild steel, stainless, aluminum, composites)

- Energy Efficiency (hybrid or electric options)

- Software Integration (AI, IoT, CAD/CAM compatibility)

- After-Sales Support

👉 Get tailored recommendations from KRRASS by contacting our experts.

8. Case Study: Smart CNC Adoption

A mid-sized European factory adopted a fully automated CNC sheet metal line in 2024. Results within one year:

- 35% increase in production output

- 25% lower energy consumption

- Significant reduction in scrap waste

- Improved ROI through predictive maintenance

This showcases how embracing CNC technology positions companies for long-term growth.

Conclusion

The fabrication future is already here, and CNC technology is leading the way. In 2025, manufacturers that embrace sheet metal trends like AI-driven systems, press brake innovation, automation, and sustainability will gain a competitive advantage.

Key Takeaways:

- CNC systems deliver precision and cost savings.

- Automation improves efficiency and reduces downtime.

- Sustainability goals are met with energy-efficient machines.

- Smart connectivity makes predictive maintenance a reality.

👉 Learn more about KRRASS’s expertise

👉 Explore our full range of CNC products

👉 Have questions? Contact us today

By leveraging CNC innovation, sheet metal manufacturers can future-proof their operations and stay ahead in a competitive global market.