Buying a press brake is not like buying a “bigger bending machine.” A press brake becomes the backbone of your forming process, and the wrong spec mix shows up every day as inconsistent angles, slow setups, higher scrap, and painful bottlenecks. The good news is that you don’t need to be a design engineer to choose the right machine—you just need to focus on the 10 specifications that truly control accuracy, capacity, and productivity.

This guide explains those 10 specs in plain English, with practical ways to size them to your parts. Along the way, you’ll see why the “cheapest press brake” often becomes the most expensive option after tooling limits, deflection issues, and real-world throughput are considered.

Table of Contents

Before You Compare Specs: Define Your Parts and Process

Your “part reality” matters more than the catalog

A press brake spec sheet is only meaningful when you match it to real parts: material type, thickness range, bend length, required inside radius, and tolerance expectations. If you buy based only on nominal tonnage and bed length, you can end up with a press brake that technically “can bend” your job, but cannot do it reliably or efficiently.

Also, be honest about your production style. If you run many part numbers with small batches, setup speed and programming features can be more important than maximum tonnage. If you run long batches, stability and repeatability can matter more than fancy software.

Decide how you bend: air bending vs bottoming vs coining

Most modern press brake work uses air bending because it’s flexible and typically requires less force than bottoming or coining. That said, air bending introduces more springback sensitivity, which makes control features (crowning, angle measurement, good backgauge) more valuable. If you do bottoming/coining for tight radii or special requirements, the tonnage and tooling requirements rise quickly, and your press brake must be sized accordingly.

Use authoritative safety references early, not after installation

Safety is part of the buying process, not a “later” upgrade. In the U.S., press brake safeguarding expectations often reference OSHA machine guarding requirements (for example, OSHA 29 CFR 1910.212) and related guidance/interpretations for press brakes.

Spec 1: Rated Tonnage and Real Working Tonnage

What “rated tonnage” really means

Rated tonnage is the maximum forming force your press brake can deliver, usually defined under specific conditions. A common misunderstanding is assuming “more tonnage” automatically means “better press brake.” In reality, you need enough tonnage with a safety margin, plus structural and control features that keep that tonnage usable across the full bending length.

How to estimate tonnage without guessing

Tonnage depends on thickness, material tensile strength, V-die opening, bend length, and method (air bending vs bottoming). Industry resources like The Fabricator explain press brake tonnage drivers and calculation steps in a practical way, which helps buyers avoid oversizing or (worse) unknowingly under-sizing. See examples like Taking a deep dive into press brake tonnage and Four steps to calculate press brake tonnage limits.

What to look for beyond the ton number

A buyer-focused press brake specification review should also ask about overload protection, tonnage distribution rules (especially for partial-length bends), and whether the machine supports controlled bending under varying loads. A press brake that survives overload is not the same as a press brake that holds angle consistency under real production patterns.

Spec 2: Bending Length and Usable Distance Between Frames

Bed length is not the same as usable bending length

Many buyers see “3 m” or “10 ft” and assume they can bend that length. But the usable length can be reduced by side frame geometry, tool overhang limits, crowning system layout, and the need to keep bends away from frame interference. A practical press brake purchase compares “maximum bending length” and “distance between side frames” to ensure your longest parts are truly bendable.

Plan for future parts without buying waste

If your current longest flange is 2000 mm, it might be tempting to buy a 2000 mm press brake. In many factories, part sizes creep upward over time, and a small length upgrade can prevent expensive rework later. The right approach is to choose a bending length that covers future demand while still fitting your floor layout, tool strategy, and material handling workflow.

Spec 3: Daylight (Open Height), Stroke, and Shut Height

Why these dimensions control “what can physically fit”

Daylight (often called open height) is the maximum distance between ram and bed when the press brake is fully open. Stroke is how far the ram travels. Shut height relates to the closed position with tooling. These dimensions decide whether you can run tall tooling, deep box forms, large return flanges, and certain hemming or specialty setups.

Hidden constraint: tool height + part geometry + handling

Even if a press brake has enough tonnage, you can still fail a job because the part cannot be rotated or repositioned due to limited daylight or throat space. This is especially common when bending complex enclosures or parts with multiple up-legs. When comparing press brakes, ask for a bending simulation check or a clearance review for your “worst case” parts, not just the typical parts.

Spec 4: Throat Depth and Working Window

Throat depth affects box work and return flange clearance

Throat depth is the distance from the ram centerline to the back frame, and it governs whether deep parts can be positioned without collision. If you bend cabinets, electrical enclosures, brackets with large returns, or parts that must be gauged deep into the machine, throat depth becomes a must-check press brake specification.

Don’t forget the “side window” problem

On paper, throat depth looks sufficient, but the side frame shape can limit lateral movement or cause interference during part rotation. A press brake that is “deep enough” may still be inconvenient if the window area is restricted. For buyers, this is one of the most overlooked sources of hidden inefficiency.

Spec 5: Deflection Control and Crowning System

Deflection is normal—uncompensated deflection is expensive

Every press brake deflects under load, especially on long bends. That deflection changes the bend angle across the length, which shows up as “good in the middle, off at the ends” (or the reverse). That is why crowning exists: it compensates for beam/table deflection so you can hold consistent angles.

Mechanical vs CNC crowning

A basic crowning method may use manual wedges, while modern machines often use CNC-controlled crowning to adjust compensation by program and load. Major press brake builders frequently highlight integrated CNC crowning as a core contributor to consistent angles, particularly on longer parts. For example, see references to CNC crowning and frame stability in bending machine brochures such as TRUMPF bending machines brochure (PDF).

What to ask on a quotation

When comparing press brake offers, ask how crowning is implemented (manual, motorized, CNC), whether compensation is automatic per program, and what the adjustment resolution is. If you bend long parts with varying material thicknesses, CNC crowning moves from “nice-to-have” to “production insurance,” because it reduces trial bends, rework, and time spent chasing angle variation.

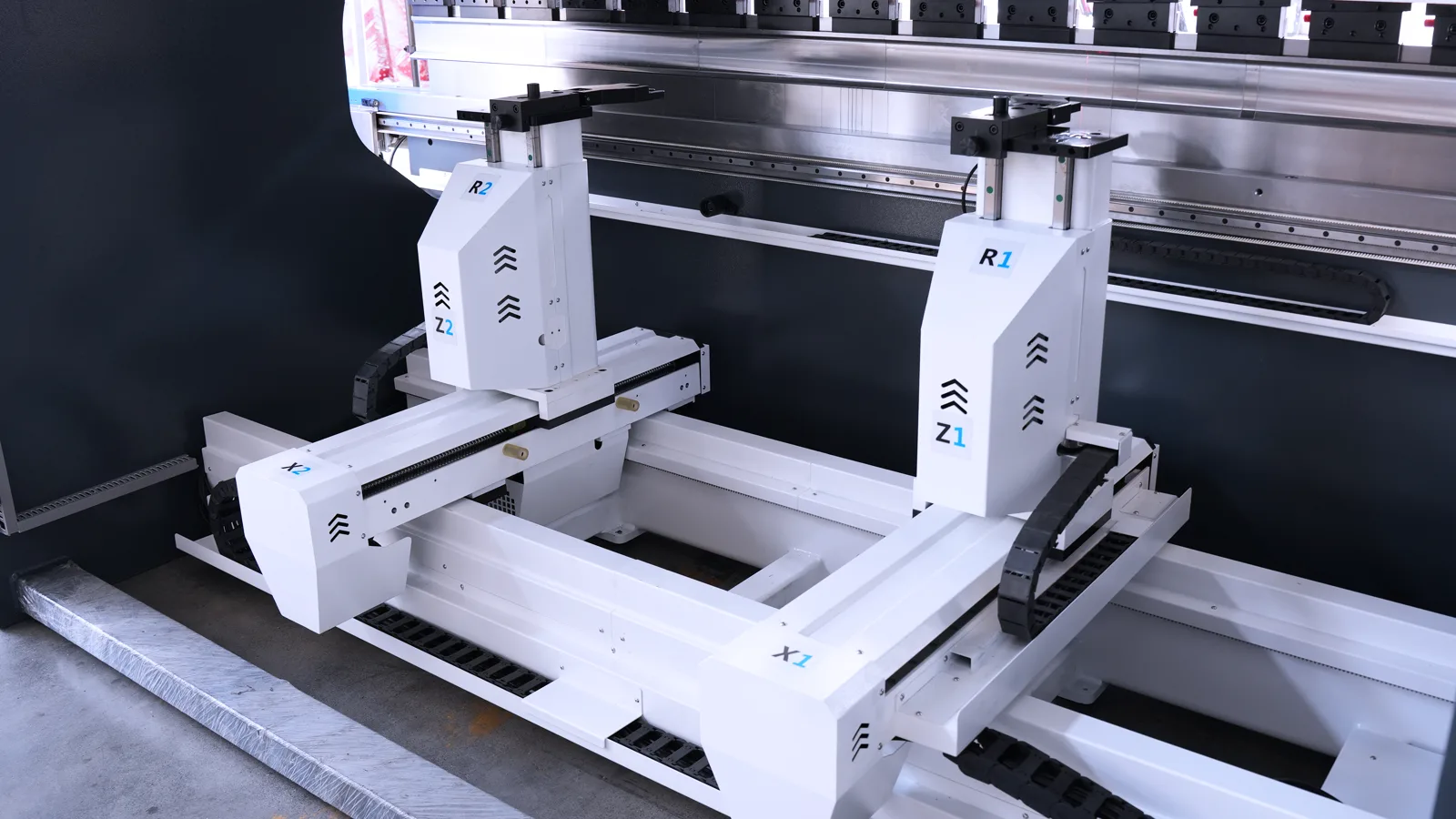

Spec 6: Backgauge System (Axes, Travel, and Real Accuracy)

Backgauge capability decides your throughput more than you expect

A press brake can have excellent tonnage and still be slow if the backgauge is limited. Backgauge axes (commonly X, R, Z1/Z2, plus optional additional axes) control how fast you can position material for multiple bends, how well you can handle tapered parts, and how efficiently you can run complex sequences.

Why “more axes” is not always the right answer

If you mostly run simple L-bends and channels, a simpler backgauge can be efficient and cost-effective. If you run complex parts with multiple bends and varying flange lengths, additional axes can save huge setup time. The best press brake buying decision matches backgauge complexity to your part complexity, rather than buying the maximum axis count “just in case.”

Repeatability beats “one-time accuracy”

Backgauge accuracy is not only about reaching a number once, it’s about repeating it over thousands of cycles. In press brake production, repeatability reduces scrap and stabilizes quality. Many manufacturers describe multi-axis backgauges as a key contributor to repeatable bending results; for an example of how mainstream builders frame backgauge capability, see press brake descriptions like TRUMPF TruBend Series information.

Spec 7: CNC Controller, Programming, and Bend Simulation

Your controller is the “operator multiplier”

A modern press brake controller is not just a screen—it’s a productivity system. Features like intuitive programming, graphical setup guidance, tool libraries, collision warnings, and step-by-step bend sequencing reduce dependency on a single expert operator. If you train new operators or shift staff between machines, controller usability becomes a real cost factor.

Offline programming and job management

If your factory runs many part numbers, offline programming can keep the press brake bending while engineering prepares the next job. Job storage, revision control, and tool setup guidance can prevent the “we used the wrong die” mistakes that quietly destroy margins. When evaluating a press brake, ask how the controller manages programs, tool data, and setup consistency across operators.

Look beyond marketing words

Many controllers claim to be “easy.” Ask for a live demo using one of your real parts. A good press brake supplier will show how the controller handles bend allowances, backgauge positioning, and simulation checks, and they will explain what data must be measured (like actual thickness) to keep accuracy stable.

Spec 8: Positioning Accuracy, Repeatability, and Angle Control

Understand what “accuracy” means on a press brake

Press brake accuracy has multiple layers: ram positioning (Y-axis), synchronization (Y1/Y2), backgauge positioning, and the final bend angle at the part. A machine can position accurately but still produce angle variation if springback changes or if deflection is not compensated properly.

Why angle measurement is becoming a competitive advantage

Advanced angle measurement systems can reduce trial bends and help hold tighter tolerances in changing material conditions. Industry discussions of precision bending often cite very tight bend-angle tolerances when adaptive systems are used; for example, MetalForming Magazine has discussed bend-angle tolerance values around ±0.2° in the context of precision bending technology.

What buyers should request in acceptance testing

If angle consistency matters, define a simple acceptance approach: same material batch, known tooling, and a multi-point check along the bend length. Ask your press brake supplier how they will verify parallelism, repeatability, and angle consistency, and whether crowning and control parameters are included in the test.

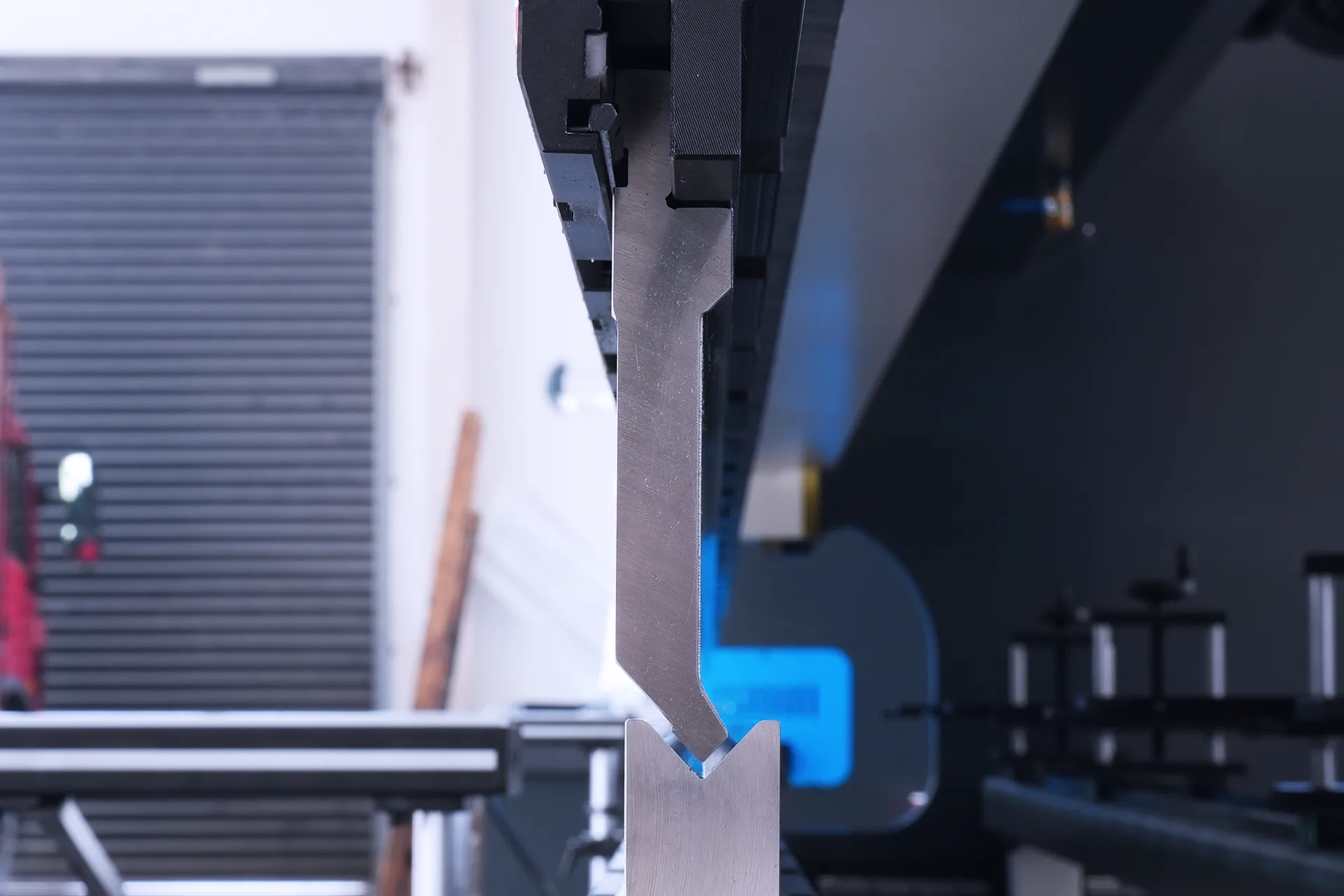

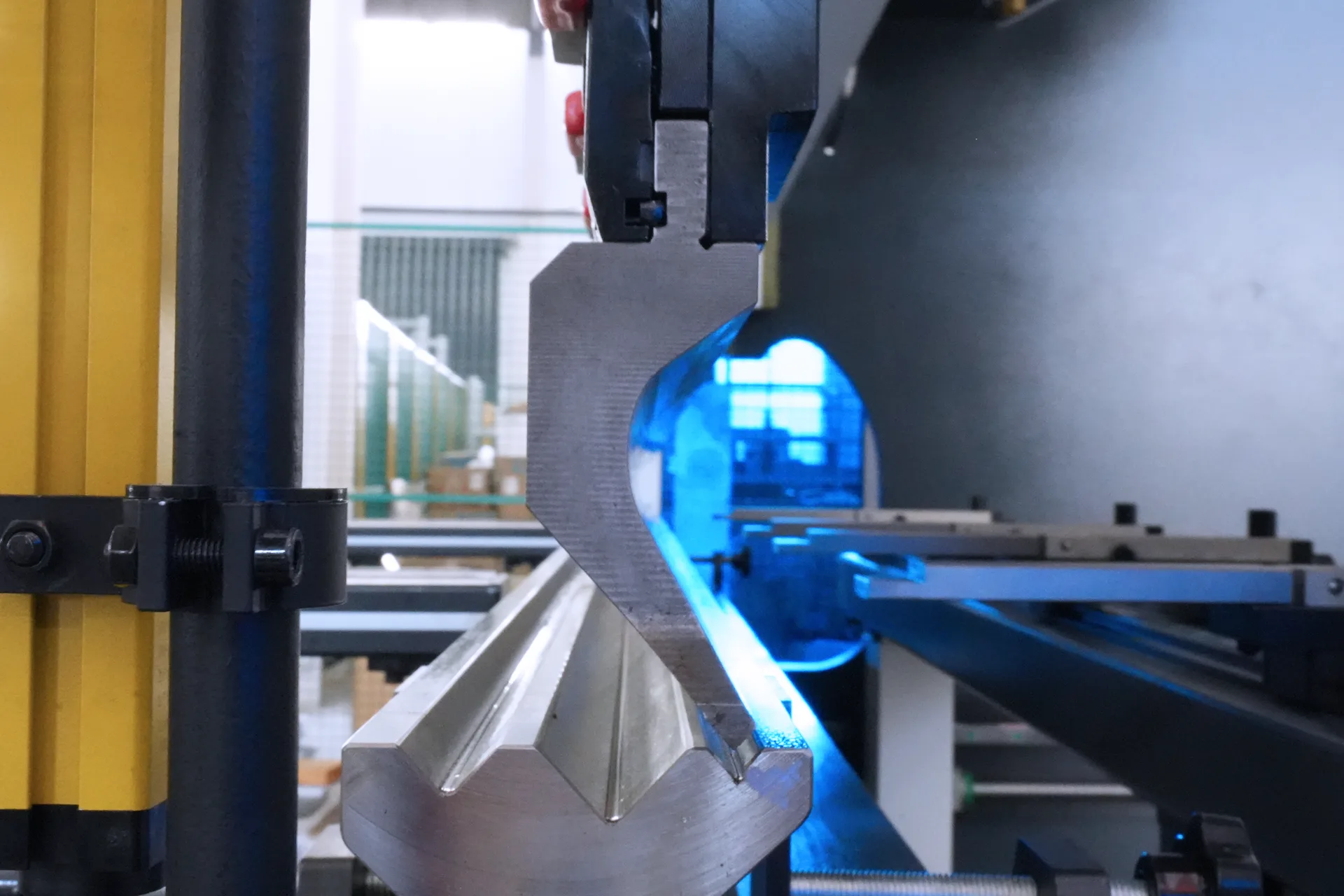

Spec 9: Tooling System, Clamping, and Die Selection Rules

Tooling compatibility can lock you in—or set you free

Press brake tooling standards vary by region and by system (different punch/die tang styles, heights, clamping types). Before buying a press brake, confirm which tooling standard it uses and whether adapters are needed. Tooling compatibility affects not only cost, but also lead time and your ability to source from multiple suppliers.

Quick-change clamping is a productivity spec

Hydraulic or pneumatic clamping, front-loading tools, and segmented tooling options can reduce setup time dramatically. If your factory changes jobs frequently, quick-change tooling can deliver ROI faster than upgrading tonnage. A press brake that takes 30–40 minutes to change tooling will never “feel fast,” even if its approach speed is impressive.

Use proven die-opening rules (and know their limits)

Die selection influences tonnage, inside radius, and surface quality. The Fabricator explains common selection logic like the “rule of 8” for V-die opening in a buyer-friendly way, and it also clarifies when the rule changes based on material and bend radius targets. See The rules of press brake tool selection.

Spec 10: Speed, Energy Use, and Automation Readiness

Speed specs that actually matter in production

Press brake catalogs may list approach speed, bending speed, and return speed, but your real throughput depends on the entire cycle: gauging, part handling, controller prompts, tool change time, and corrections. If you handle large parts manually, ergonomics and backgauge behavior can matter more than pure ram speed.

Drive technology: hydraulic vs servo-electric

Hydraulic press brake designs remain popular because they are robust and versatile across a wide range of tonnages and part types. Servo-electric solutions can offer energy and noise advantages for certain applications, especially when optimized for frequent short cycles. If you are comparing drive types, look for credible references that explain how modern systems integrate features like CNC crowning and adaptive control in real machines; examples include technology brochures from established builders such as Prima Power servo-electric bending technology (PDF).

Think about automation even if you start manual

You may not add a robot today, but choices like backgauge layout, controller capability, guarding strategy, and tooling quick-change readiness can make future automation much easier. Buying a press brake with a clear automation path is often cheaper than replacing a “manual-only” machine later.

Common Buying Mistakes (and How to Avoid Them)

Mistake 1: Buying tonnage without checking deflection control

A press brake with high tonnage but weak deflection compensation can produce inconsistent angles on long parts. That inconsistency causes extra trial bends and operator “workarounds,” which quietly increases cost per part.

Mistake 2: Ignoring your tooling ecosystem

If you already own a tooling library, the wrong press brake tooling interface can force expensive adapters or new tools. If you are starting from zero, pick a tooling system that is easy to source, quick to change, and compatible with how you plan to grow.

Mistake 3: Treating safety as an afterthought

Retrofitting guarding and safety devices can be costly and disruptive. Use recognized references during planning—OSHA guidance and interpretations around safeguarding expectations for press brakes are helpful starting points, and you can also review consensus safety standards such as ANSI B11.3 listings for machine-specific safety requirements.

Why KRRASS Press Brake Buyers Reduce Risk

Engineering that matches real factory work

At KRRASS, we focus on press brake configurations that fit real production: stable frame design, practical crowning options, reliable backgauge setups, and controller features that shorten the learning curve. A good press brake is not only accurate on day one, but also predictable after months of daily cycles.

Support that protects your uptime

A press brake is a long-term asset, so we build our delivery around training, documentation, spare parts planning, and remote support readiness. When your press brake is the bottleneck machine, fast support is not “service”—it is production capacity.

Transparency in specs and acceptance

We encourage customers to define acceptance criteria based on their parts and tolerance needs. That includes discussing tonnage margin, deflection behavior, tooling strategy, and backgauge repeatability before the purchase is finalized, so the installed press brake matches the expectations that justified the investment.

A Practical Press Brake Buying Checklist (Use This on Every Quote)

Confirm the job envelope first

Verify your maximum thickness, material strength range, and longest bend length. Then check whether daylight, stroke, and throat depth support your deepest part geometry without collisions.

Match productivity features to your workload

If you do frequent changeovers, prioritize quick clamping, controller usability, and tool libraries. If you run long batches, prioritize stability, crowning quality, and repeatability.

Ask the supplier to size the press brake using your parts

Provide 3–5 representative drawings and ask the supplier to recommend a press brake configuration and tooling strategy. A serious press brake partner will explain the trade-offs in plain terms and show why the selected specs reduce risk and improve throughput.

FAQ

What is a press brake used for?

A press brake is a machine that bends metal sheets into different shapes and angles. It is commonly used in manufacturing processes to create items like brackets, enclosures, and other metal components. By applying pressure in a controlled manner, press brakes can form metal accurately and efficiently.

How do I choose the right tonnage for my press brake?

Choosing the correct tonnage is crucial for effective bending. Tonnage refers to the maximum force your press brake can apply. You need to consider the thickness and type of metal you are using, as well as the size and shape of the bends you want to make. It’s essential to have enough tonnage to handle your work while allowing for a safety margin.

What is the difference between rated tonnage and real working tonnage?

Rated tonnage is the maximum amount of force your press brake can generate under ideal conditions. Real working tonnage is how much force the machine can reliably apply in practical use. It’s important to look at both to ensure the machine can handle your specific bending needs.

What is daylight in a press brake?

Daylight, also known as open height, is the distance between the top of the ram and the bed when the machine is fully open. This measurement is crucial because it determines how thick or tall the materials you can bend are, and it affects the setup of your tooling.

How does the backgauge work in a press brake?

The backgauge is a system that helps position the metal sheets accurately for bending. It adjusts the sheet’s location based on the programmed dimensions, which enhances repeatability and reduces setup time for multiple bends. A good backgauge system can significantly improve the efficiency of your bending process.

What is the ideal bending length?

The bending length is the length of the metal that can be bent in one go. However, what matters more is the usable length, which accounts for the machine’s side frames and tooling setup. Ensure that the bending length can accommodate your long parts and consider future part sizes when making a decision.

Why is deflection control important?

Deflection happens when the press brake bends under load, which can affect the accuracy of your bends. A good deflection control system ensures consistent angles throughout the entire length of the part by compensating for the bending that occurs. This is essential for maintaining high-quality production.

What should I ask about safety when buying a press brake?

Safety is paramount when working with press brakes. Ensure that the machine meets OSHA safety standards and inquire about safety features like machine guarding and emergency stop functions. Understanding safety protocols will help you create a safer working environment.

How can I optimize programming for new parts?

Many modern press brakes come with user-friendly controllers that help operators program jobs more efficiently. Look for features like graphical setup guides and job management systems that allow you to save and store different programs. This can speed up the programming process significantly.

What are common mistakes to avoid when buying a press brake?

Common mistakes include not checking for proper deflection control, ignoring tooling compatibility, and treating safety as an afterthought. Always ensure the press brake meets your bending needs, and don’t forget about the long-term implications of your purchase, such as the cost of tooling and potential safety upgrades.