Nanjing, China, December 25, 2023

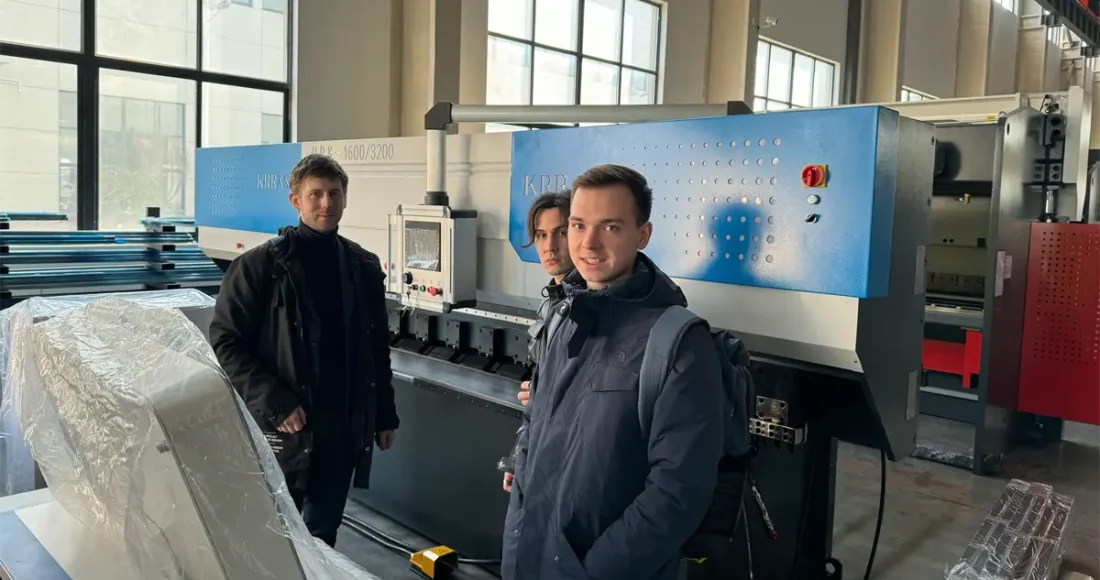

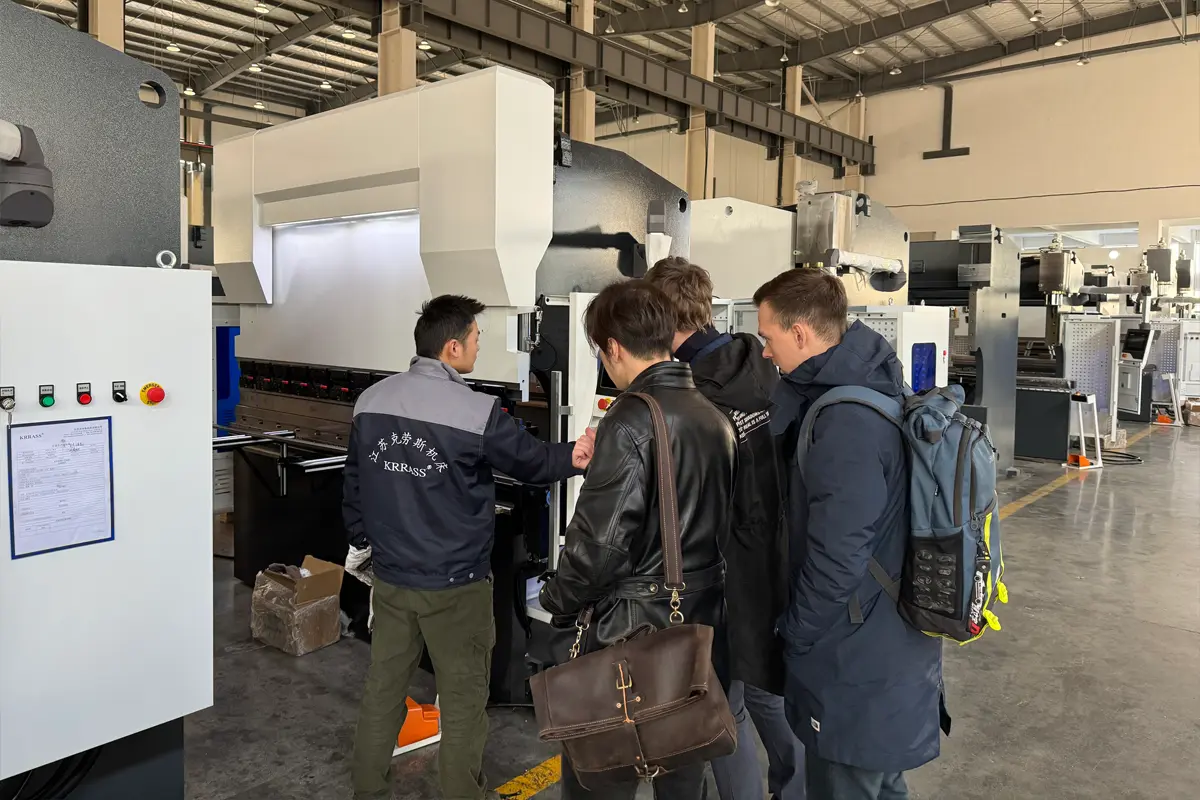

KRRASS recently welcomed a group of customers from Russia who visited the company’s factory to learn about and purchase equipment.

During the visit, the customers toured KRRASS’s factory, learned about the company’s production process and products, and watched demonstrations of some of KRRASS’s press brakes. They were impressed with KRRASS’s press brake products.

Ultimately, the customers decided to place an order for two of metal forming machines: a CNC Press Brake, model MB8-110T3200 DA-53T; and a Guillotine Shears, model QC11K-6X3200.

The MB8-110T3200 DA-53T is a high-end CNC press brake with the following features:

- Modern and stylish design with high-quality construction.

- Latest high-frequency hydraulic control technology for faster, more efficient, and more accurate bending.

- A combination of rack heat treatment, whole-machine rigidity optimization, and hydraulic crowning structure ensures bending precision.

- Optimized parameters and core configuration for stable performance and easy operation.

- DA53T controller with standard 4+1 axes (Y1, Y2, X, R, and W axis crowning) and interchangeable dies for bending complex shapes.

- Full-closed-loop electro-hydraulic servo synchronous control technology for precise slide block positioning and parallel alignment to the worktable.

- CNC controller automatically compensates for worktable deflection to ensure uniform bending angle throughout the workpiece length.

- Hydraulic or mechanical crowning methods can be used to achieve uniform precision over the entire worktable length. The hydraulic crowning system uses a group of oil cylinders to move the worktable relative to each other, forming an ideal curve that ensures the relationship between the sliding block position and bearing force remains constant. The compensation amount is determined by the CNC controller based on plate thickness and material characteristics.

The QC11K-6X3200 shearing machine has the following highlights:

- Sleek Euro design: Robust construction with precision-engineered components for optimal performance.

- Friction-free cutting: Rolling guide rails minimize wear and tear, ensuring long-lasting accuracy.

- Easy blade adjustment: CNC system controls blade clearance for consistent, high-quality cuts.

- Stable operation: Reliable hydraulic system and timing transmission for smooth, dependable performance.

- Convenient scribing: Light and shadow line facilitates precise cut measurements.

- Durable blades: High-quality alloy steel handles demanding materials with ease.

- Operator comfort: Ergonomic design and rolling ball workbench for fatigue-free operation.

- Enhanced safety: Unique guard protects operators while handling small pieces.

Through the visit, the customers gained a deeper understanding of the KRRASS brand and further strengthened their trust and cooperation with KRRASS. The customers expressed their hope to have more cooperation opportunities in the future.

KRRASS is a leading company that is dedicated to providing high-quality metal forming machines to customers around the world. KRRASS’s products are renowned for their outstanding performance, reliable quality, and comprehensive after-sales service.