HRK series V Grooving Machine is the latest equipment produced by KRRASS specially for the Sheet Metal industry.

- HRK series V Grooving Machine is compact in structure, reliable in performance, easy operation, no deformation.

The structure consists of three sets of servo motor drive system, hydraulic clamping system and main steel frame.

- X-axis System

The Y-axis system of the machine is composed of ECMA-F20830 main motor, AC servo motor, high-precision gear rack and linear guide rail, etc.

The function of servo motor is to drive the cutter seat through planetary reducer to make rectilinear motion on the linear guide rail. - Y-axis System

The Y-axis system is composed of two E21320 servo motor (Y1, Y2), with Ball screw, linear guide.

The motor drives the ball screw and the back gauge to move linearly on the guide rail, and provides accurate positioning for the back gauge mechanism.

Y1 and Y2 two servo motors are used to effectively control synchronization and reduce errors caused by belt transmission or connecting rod transmission. - Z-axis System

The Z-axis system is composed of C20604 servo motor, timing belt, timing wheel, ball screw, cutter holder and so on. Its function is to drive the ball screw and cutter seat make rectilinear motion through timing belt and timing wheel, and provide precise positioning power for the tool holder. - Hydraulic System

The hydraulic system is divided into two groups (backgauge hydraulic holding system and front groove holding system )

The backgauge hydraulic holding system.Its function is to provide clamping force before grooving and tightly press the plate for feeding.

The front groove holding system,its function for provide clamping before every grooving.

The advantages of the hydraulic system greatly improve the pressing capacity and increase the depth of the grooving. - Electrical Control System

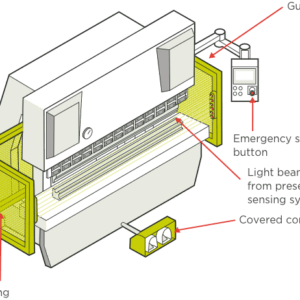

The electrical control system is composed of PLC, actuator, touch screen, electric control element, electrical cabinet, etc. the electrical cabinet is installed in the side wall of the machine, which is convenient for maintenance and higher protection performance. Any work can be realized by controlling the touch screen.

| No. | Content | Required Parameter |

|---|---|---|

Learn more about our products, please visit and subscribe to our Youtube channel